Designing an aluminum box involves several considerations such as the size, shape, material thickness, and joining method. Here are some steps to follow:

-

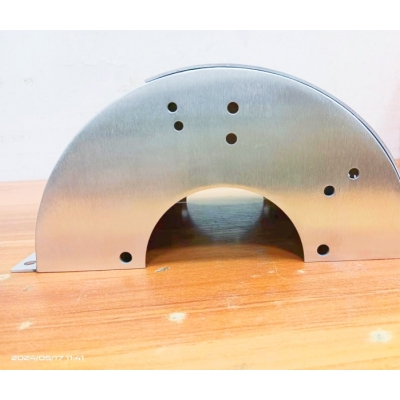

Determine the size and shape of the box: Consider the purpose of the box and the dimensions of the components that will be housed inside. Sketch out the rough design on paper or using a 3D modeling software.

-

Choose the appropriate aluminum material: The type of aluminum material chosen should be based on the requirements for strength, corrosion resistance, and aesthetics.

-

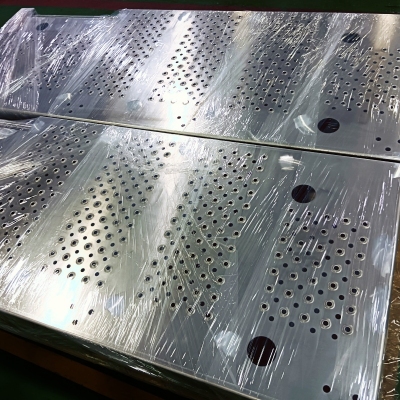

Determine the thickness of the aluminum material: The thickness of the aluminum material should be chosen based on the size of the box, the weight of the contents, and the expected level of stress.

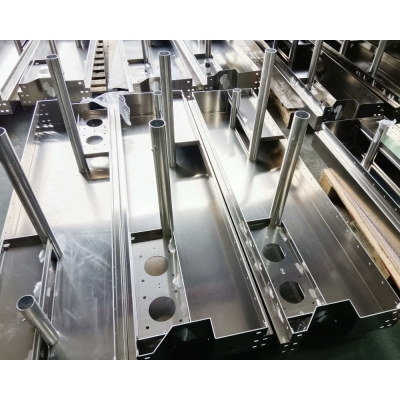

4. Decide on the joining method: There are several joining methods for aluminum boxes, such as welding, brazing, and adhesive bonding. Choose the appropriate method based on the thickness and type of aluminum material used.

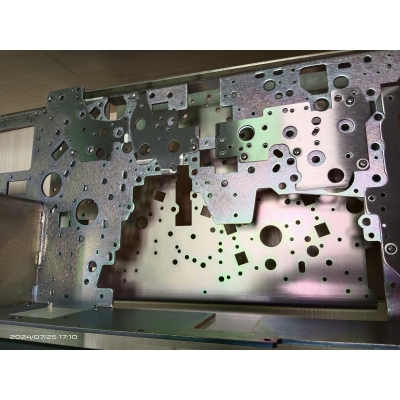

5. Fabricate the box: Use the appropriate tools to cut and shape the aluminum material, then use the chosen joining method to assemble the box.

6. Finish the box: The aluminum box can be finished with anodizing, powder coating, or other methods to provide a protective layer and enhance the appearance.

Remember to always prioritize safety when working with metal fabrication tools and equipment.

Project Links:

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure | Custom Aluminium Box | Custom Steel Box | Metal Box Supplier | Metal Enclosure Manufacturer | Sheet Metal Enclosure Manufacturers | Metal Enclosure Box Manufacturer | Metal Enclosure Manufacturer | Aluminium Box Manufacturer | Outdoor Equipment Enclosures | Aluminium Box Manufacturers | Equipment Enclosures Metal | Metal Enclosure Box | Metal Enclosure | Enclosure Box Price | Sheet Metal Manufacturers | Sheet Metal Manufacturing companies | Custom Made Aluminium Boxes | Custom Made Metal Box | Aluminum Sheet Metal Fabrication | Aluminium Sheet Metal Fabrication | Auminium Tool Boxes Made to Order | Custom Metal Enclosures | Custom Stainless Steel Box | Custom Made Aluminum Boxes | Metal Box Manufacturers | Custom Steel Enclosures | Custom Stainless Steel Enclosures | Custom Metal Box | Custom Aluminium Box | Sheet Metal Fabrication Supplier | China Sheet Metal Fabrication | Custom Sheet Metal Fabrication | Sheet Metal Fabrication Services | Metal Manufacturing in China | Aluminum Box Fabrication | Sheet Metal Box Fabrication | Sheet Metal China | Precision Sheet Metal Fabrication | Custom Aluminum Box Fabrication | Custom Metal Box Fabrication