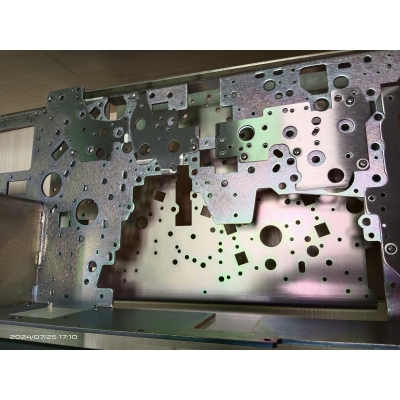

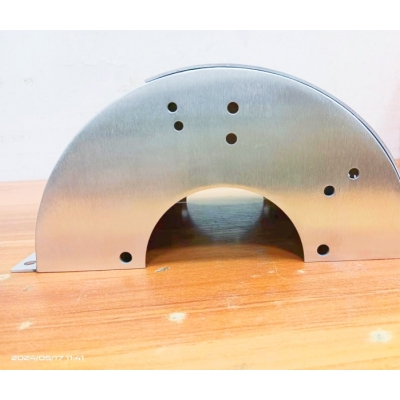

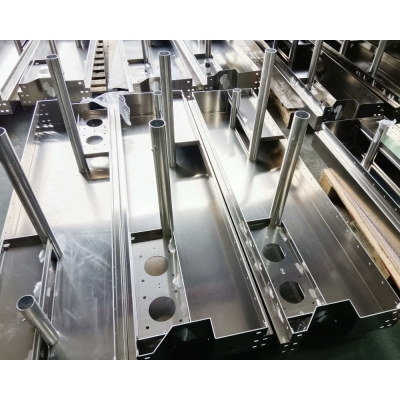

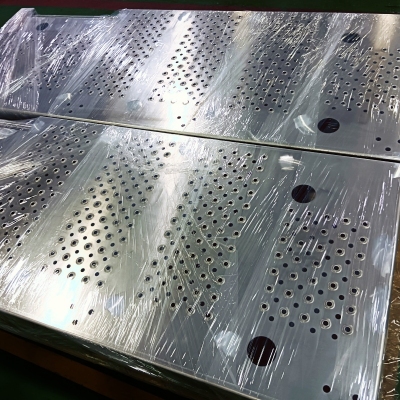

China Sheet Metal Fabrication Factory

MOQ: 1PC Price: Negotiable. Certification: ISO9001 2015

Lead time:7-15 Days, Depend on Your Quantity.

Send Us the Drawings for Profefessional Services and Accurate Cost Estimation of JIATONG XJ Origin Factory Competitive Prices. Welcome Your Visit or Video Audit onsite.

China Sheet Metal Fabrication Factory

How to Inspect, Check and Control Quality of Sheet Metal Parts?

Sheet metal fabrication quality control involves ensuring that fabricated parts meet the required specifications, standards, and customer expectations. Here are key steps and considerations for effective quality control in sheet metal fabrication:

Design and Engineering Controls:

Detailed Drawings and Specifications: Provide clear and detailed drawings with specifications for dimensions, tolerances, material type, thickness, surface finish, and any other critical requirements.

Design for Manufacturability (DFM): Optimize designs for efficient fabrication processes while ensuring that parts can be produced within specified tolerances and quality standards.

JIATONG REPRESENTATIVE FACILITES& CAPABILITIES IN-HOUSE.

Tooling and Equipment Management:

Tool Maintenance and Calibration: Regularly maintain and calibrate fabrication tools, dies, punches, and machines to ensure accurate and consistent production.Equipment Capability Verification: Validate equipment capabilities periodically to ensure they can achieve required tolerances and quality standards.

Process Control and Inspection:

First Article Inspection (FAI): Perform initial inspection of the first fabricated part to verify it meets all design specifications.In-Process Inspection: Conduct inspections at critical stages of fabrication to identify any deviations from specifications. This may include dimensional checks, surface inspections, and material testing.

Statistical Process Control (SPC): Implement SPC techniques to monitor key process parameters and detect variations that could affect product quality.

Quality Assurance Procedures:

Documentation: Maintain comprehensive records of inspections, tests, and process parameters. This includes documenting inspection results, deviations, and corrective actions taken.Non-Conformance Management: Establish procedures for handling non-conforming parts, including segregation, investigation of root causes, and implementation of corrective and preventive actions (CAPA).

Employee Training and Skill Development:

Training Programs: Provide training for operators, inspectors, and quality personnel on fabrication processes, quality standards, and use of inspection tools.Skill Development: Encourage continuous improvement and skill development among employees to enhance their ability to identify and resolve quality issues.

Supplier Quality Management:

Supplier Evaluation: Evaluate and select suppliers based on their ability to meet quality requirements. Conduct audits and inspections of supplier facilities as needed.Supplier Performance Monitoring: Monitor supplier performance through metrics such as quality, delivery reliability, and responsiveness to quality issues.

Continuous Improvement:

Quality Metrics and Analysis: Use quality metrics and data analysis to identify trends, opportunities for improvement, and areas needing corrective action.Feedback and Customer Satisfaction: Gather feedback from customers on product quality and performance to drive continuous improvement efforts.

By implementing these quality control measures consistently, sheet metal fabrication companies can ensure that their products meet high-quality standards, minimize defects, and enhance customer satisfaction.

Related Links:

sheet metal fabrication company china | china sheet metal forming manufacturers | china sheet metal fabrication manufacturers | china custom sheet metal parts | china sheet metal fabrication companies | china sheet metal fabrication factory | sheet metal fabrication companies in china | sheet metal parts manufacturing china | china sheet metal parts manufacturers | china sheet metal parts company | china metal enclosure manufacturers | china aluminum sheet metal fabrication manufacturers | china sheet metal manufacturing manufacturers