Methods of Remove Burrs

According to the different machining methods of mechanical parts, burr can be divided into forging burr, casting burr, stamping burr, cutting burr, plastic forming burr and so on. In the process of machining, burr is everywhere. No matter how advanced and precise equipment you use, it will be born with the product. So I'll share some ways to remove burrs.

1. Manual deburring

Manual deburring is also a common method used by general enterprises. It uses files, sandpaper, grinding heads and so on as auxiliary tools. The labor cost is expensive, the efficiency is not very high, and it is difficult to remove complex cross holes. The technical requirements for workers are not very high, so it is suitable for products with small burr and simple product structure.

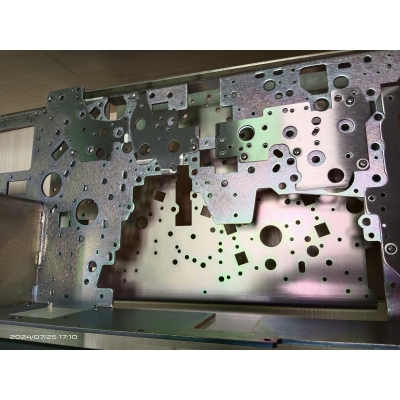

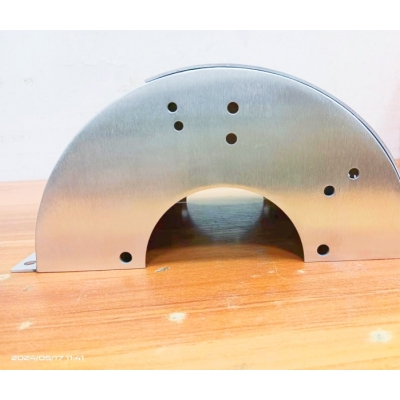

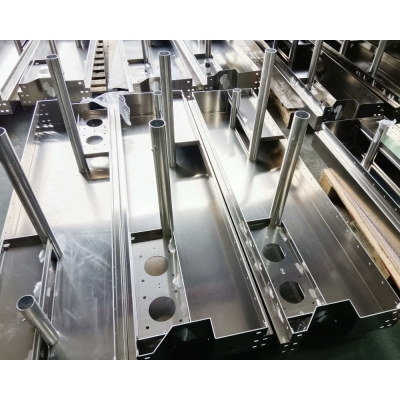

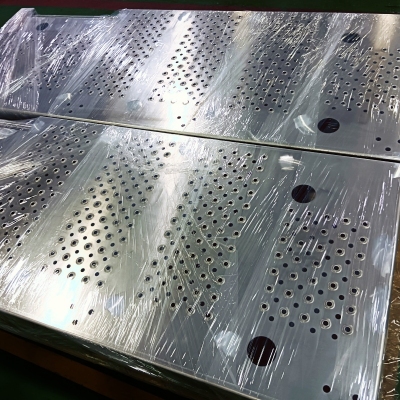

Laser Cutting/Grinding/Welding of Custom Metal Boxes

2. Chemical deburring

Chemical deburring is to put the cleaned metal parts into the chemical solution, so that the metal on the surface of the parts will be transferred to the solution in the form of ions. These ions gather on the workpiece surface and form a viscous film with high resistance and low conductivity through chemical reaction to protect the workpiece surface from corrosion. The burr protrudes from the surface, and the chemical reaction will remove the burr. It has the advantages of high production efficiency, can remove burrs in large quantities and save a lot of labor. The labor intensity is reduced, the deburring effect is very ideal, and the economic benefit of the enterprise can be improved.

3. Freeze deburring

The burr is quickly embrittled by cooling, and then the burr is removed by shot blasting. The price of freezing deburring equipment is about US $30000 to US $50000, which is suitable for products with small burr wall thickness and small products.

4. Water jet deburring

With water as the medium, its instantaneous impact force is used to remove the burrs and flash produced after processing, and the purpose of cleaning can be achieved at the same time. The equipment is expensive. It is mainly used in the heart of automobile and the hydraulic control system of construction machinery.

5. Grinding and deburring

Such deburring methods include vibration, sand blasting, roller and other methods, which are widely used by enterprises at present. There is a problem that the removal is not very clean. It may be necessary to deal with the residual burr manually or cooperate with other methods to remove the burr. Grinding and deburring is suitable for small products with large batch.

If you want to custom sheet metal boxes, please contact us at jiatong028@dgjiatong.com