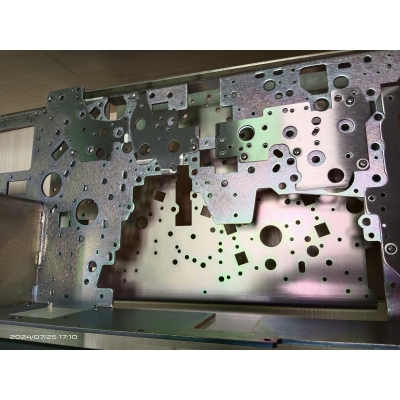

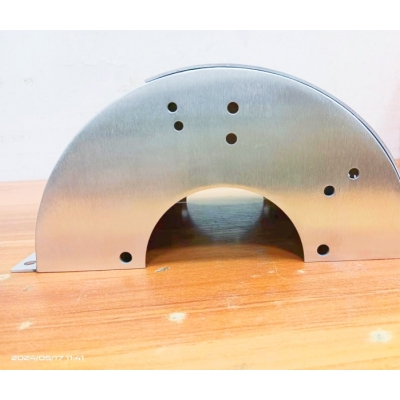

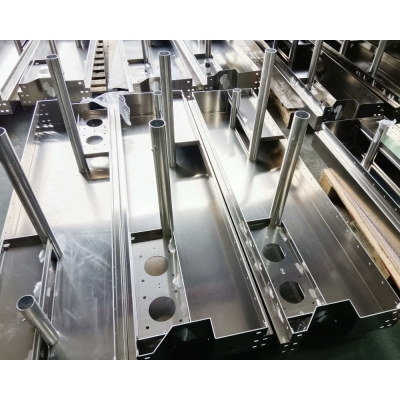

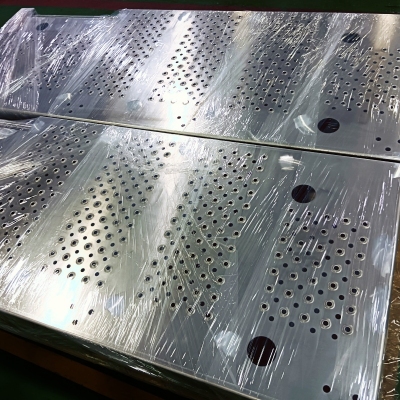

Metal Manufacturing Company

The surface treatment of sheet metal processing process is recognized by many industries for its decorative and protective effects on the surface of products. In the sheet metal processing industry, the surface treatment methods usually used are electroplating, spraying and some other surface treatment methods.

1. Electroplating is divided into: galvanizing, nickel plating, chrome plating, etc.; it mainly forms a protective layer on the surface of the material, which plays a protective and decorative role.

2. Spraying is divided into two types: spraying paint and spraying powder, which are used to spray paint onto the surface of sheet metal workpieces with a spray gun after the material has been pretreated, and the paint forms a coating on the surface of the workpiece. After drying, it plays the role of protection.

3. Other surface treatment methods: anodic oxidation, chromate, brushing, sandblasting, oxidation, etc.