Industries

Introduction to the Application Range of Sheet Metal Processing:

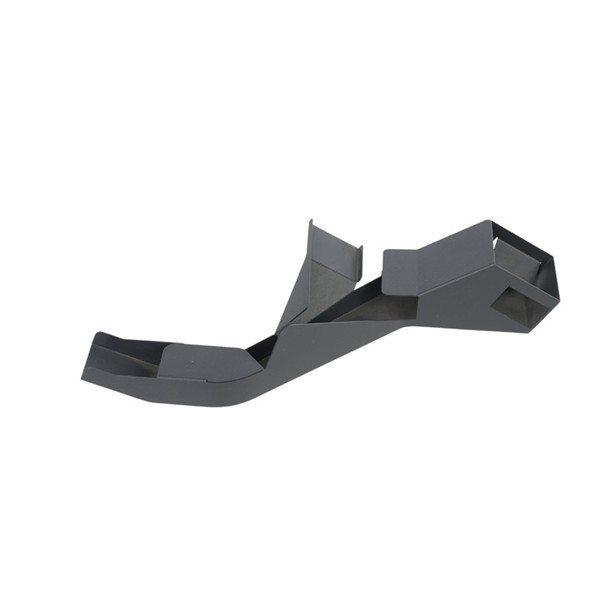

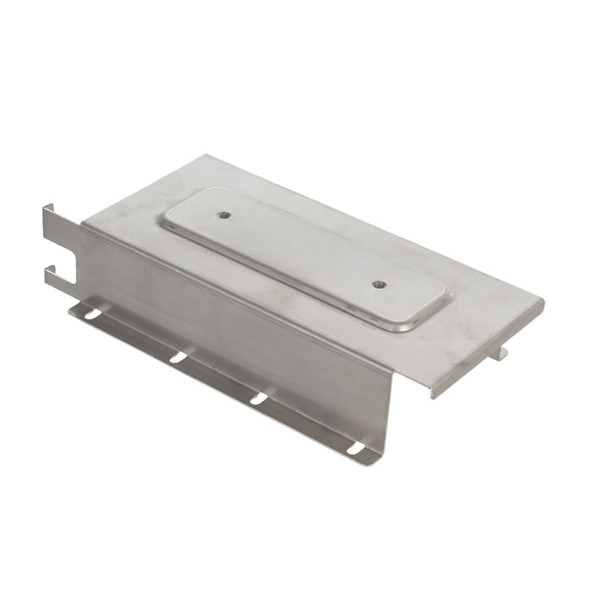

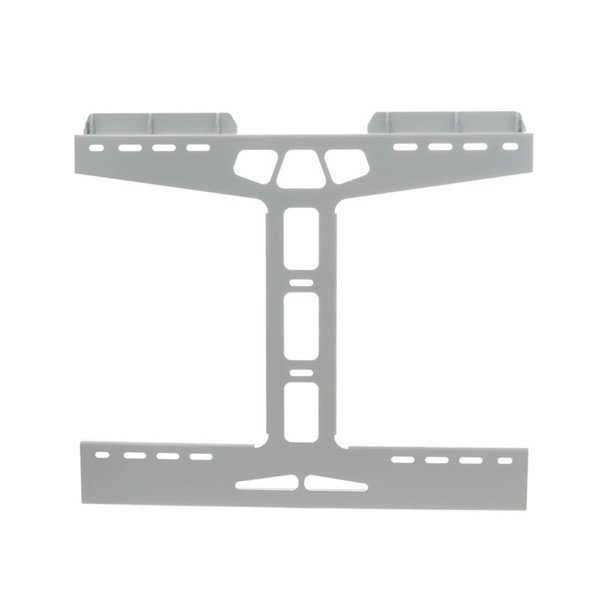

Sheet metal products have the characteristics of light weight, high strength, electrical conductivity, low cost, and good mass production performance. Widely used in electronic appliances, communications, automotive industry, medical equipment and other fields. For example, in the computer case, the mobile phone, MP3, and sheet metal are indispensable components. With the wider application of sheet metal, the requirements for Sheet metal are also getting higher and higher. In fact, the overall requirements for sheet metal parts are not very high, and only focus on assembly, while the requirement for precision sheet metal is to strictly enforce tolerances. If the out-of-tolerance energy assembly fails, its tolerance requirements are also higher than the normal level. The requirements for precision sheet metal processing will be more stringent.Since sheet metal products are widely used in almost all manufacturing industries, >>>the Main Industries Include: communication electronics, automobile, motorcycle, aerospace, instrumentation, household appliances industry,etc Under normal circumstances, most of the metal forming parts of various electromechanical products use sheet metal technology, of which stamping technology is suitable for mass production, and CNC sheet metal technology is suitable for precision production. my country's sheet metal processing industry has gone to the world, and has a certain market share in many customers in the world. Sheet metal processing operations are increasingly moving in the direction of high automation. In the future, the application of sheet metal machining will become more and more extensive.

The Main Application Scope of Sheet Metal Parts:

Sheet metal products have the characteristics of light weight, high strength, electrical conductivity, low cost, and good mass production performance. For example, in computer cases, mobile phones, and MP3, sheet metal is an essential component. Also used in the manufacture of medical devices, car and truck (van) bodies, aircraft fuselage and wings, medical tables, building roofs (architecture) and many other applications. In short, sheet metal processing has a very wide range of uses, which brings a lot of convenience to our production and life.

So Where are These Parts Made?

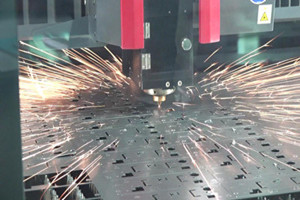

Sheet metal processing plants large and small. Sheet metal processing operations are often required in parts processing units and in the industrial field. In fact, this statement is relatively general, because it covers a lot of process methods and parameter information during processing. This processing work also has high requirements for the operator. The operator needs to understand the sheet metal processing process, and also be familiar with the application of sheet metal equipment and the input method of parameter information. In simple terms, sheet metal processing mainly includes processing methods such as laser cutting or shearing, CNC bending, stamping, and CNC punching. It is necessary to select the appropriate operation method according to the actual needs. The process of sheet metal processing directly determines the quality of our sheet metal processing.

Process Characteristics of Sheet Metal Processing:

Sheet metal s thinner than steel, so it is lighter in mass. Sheet metal processing adopts cold working technology, so it has a relatively large strength and is very hard. In addition, sheet metal and steel can pass current and have good electrical conductivity. And in terms of price, it has a good cost performance compared to other steel processing methods.

Increasing Demands on Sheet Metal Processing:

As the application of sheet metal becomes more and more extensive, the requirements for sheet metal are also getting higher and higher. In fact, the overall requirements of sheet metal parts are not very high, but they only pay more attention to assembly, but the requirement of precision sheet metal is to strictly enforce tolerances. Poor assembly is not qualified, and its tolerance requirements are also one level higher than normal, so the requirements for precision sheet metal processing will be more stringent.

Sheet metal manufacturing is the blanking or cold and hot forming of sheet metal materials, aluminum profiles and pipe fittings without changing their cross-sectional characteristics. Then the assembly is carried out by means of electric welding, riveting and screw connection, and the production and manufacturing mode of the specified metal structure is produced. The key involves a variety of technical types of work, such as milling, blanking, stamping die, metal material drilling, electric welding, heat treatment process, surface treatment, riveting and assembly.

Application of sheet metal manufacturing:Sheet metal manufacturing has a series of advantages such as manufacturing efficiency, stable quality, low cost and can produce and manufacture complex products and workpieces. Therefore, it is widely used in the application fields of mechanical equipment, vehicles, airports, light industry, motors, household appliances, electrical products and their daily necessities, and occupies a key influence. According to the survey, sheet metal parts account for 60% ~ 70% of auto parts; Airfield sheet metal parts account for more than 40% of the whole machine parts; Mechanical and electrical engineering, instruments and equipment and sheet metal parts in instrument panel account for 60% ~ 70% of the number of production and manufacturing accessories; Sheet metal parts account for more than 85% of accessories in electronic equipment; The sheet metal parts of daily appliances in the sales market account for more than 90% of the total metal manufacturing.

With the development of science and technology and the development of manufacturing technology, a large number of new technologies such as sheet metal CAD, cam and CAE have been applied. Many new machines and equipment such as blanking, forming, electric welding and welding of NC machine tools (such as optical fiber laser cutting, plasma cutting machine, water knife cutting machine, rotary head press of NC machine tools, sheet metal bending of NC machine tools, welding manipulator, robot welding, etc.) have been widely used in various fields.

At this stage, the technology of sheet metal manufacturing is developing rapidly, fully automatic, precision and stability. A variety of rapid presses, stamping die flexible manufacturing (FMS) with the functions of full-automatic production and manufacturing, full-automatic transportation and discharging, and presses for sheet metal manufacturing of various NC machine tools have successively obtained the development, design and development trend. It can be predicted that the technical strength of sheet metal manufacturing may further rise, the main uses of sheet metal prefabricated components may be more and more widely, and the total number of applications may be more and more.

Because most sheet metal manufacturing is the production and manufacturing of cold or hot separation and forming of raw materials without changing the cross-sectional characteristics of sheet metal materials, aluminum profiles and pipe fittings. Moreover, the produced metal material causes plastic deformation below the manufacturing hardening temperature, so it does not cause cutting. It can be made into a variety of goods with different shapes, specifications and characteristics, and the steel frame structure goods produced and manufactured have high compressive strength and bending stiffness, which can make full use of its bearing capacity. In the whole production and manufacturing process of sheet metal structure, each accessory constituting the structure can be assembled into prefabricated components according to the position, specification correlation and precision regulations, and according to the connection methods such as electric welding, riveting, bite or expansion.

Therefore, the coordination ability of the design scheme is large. Based on the above analysis, the key features of sheet metal manufacturing are as follows:

① Compared with the manufacturing of forged and cast parts, sheet metal prefabricated components have the advantages of light weight, saving metal composites, simple manufacturing process, reducing product cost and saving production cost.

② Most of the sheet metal prefabricated components manufactured by laser welding have low manufacturing accuracy and large welding deformation, so there is a large amount of deformation and correction after welding.

③ Because the weldment cannot be disassembled and connected and cannot be repaired, it is necessary to adopt useful assembly methods and assembly procedures to reduce waste. It is often necessary to carry out on-the-spot assembly for large, medium-sized or large commodities, so it should be tried in the factory first. In the trial, the detachable connection should be used to temporarily replace the non-detachable connection.

④ In the whole process of assembly, it is often necessary to select, adjust and accurately measure and test the product quality for several times.

Sheet Metal Main Machining Process